Statutory Safety Audit –IS 14489 :2018

Safety Audit (As Per IS 14489:2018)

A statutory safety audit is a legally required management tool for any organisation to review the current OHS systems.

The main purposes of the safety audit are-

- To carry out a systematic critical appraisal of all potential hazards involving personal, plant, services, and operation methods.

- To critically examine the working conditions of hazardous-nature plants and may lead to accidents.

- To assess the effectiveness of work practices and procedures used in the plant.

- To evaluate the effectiveness of the existing safety and health management system and suggest recommendations for implementation by the management.

SCOPE OF INDUSTRIAL SAFETY AUDIT

The scope of the safety audit is limited to the safety and health of workers employed in the manufacturing processes and operations and also the safety of the plant and equipment used in the factory. The Audit is carried out as per the requirement under IS 14489 and the various Legislative requirements such as the Factories Act, 1948 and the state Factories Rules, Environment (Protection) Act, 1986 and Rules made there under and other applicable Statutes. Besides management systems audit, technical aspects of plant activities namely, storage and handling of hazardous substances, Emergency Preparedness, process and operational safety review, transportation safety, testing and examination of plant and equipment, housekeeping, waste disposal system, fire prevention and control, etc. would also be audited.

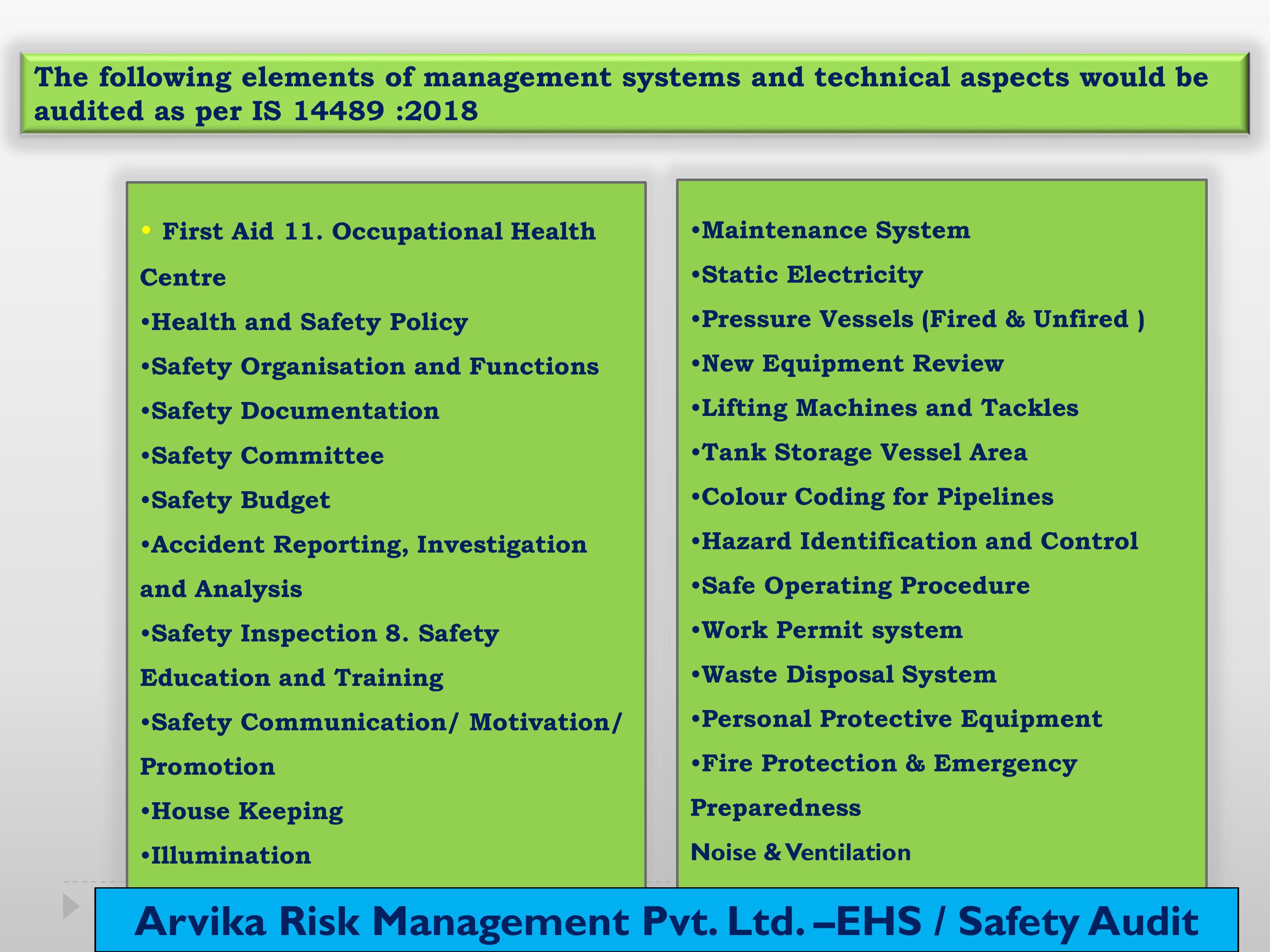

The following elements of management systems and technical aspects would be audited as per IS 14489 :2018

-

Health and Safety Policy

- Safety Organisation and Functions

- Safety Documentation

- Safety Committee

- Safety Budget

- Accident Reporting, Investigation and Analysis

- Safety Inspection 8. Safety Education and Training

- Safety Communication/ Motivation/ Promotion

- First Aid 11. Occupational Health Centre

- House Keeping 13. Noise 14. Ventilation

- Illumination

- Hazard Identification and Control

- Safe Operating Procedure

- Work Permit system

- Waste Disposal System

- Personal Protective Equipment

- Fire Protection 22. Emergency Preparedness

- Plant Layout and Area Classification

- Static Electricity

- Pressure Vessels (Fired & Unfired )

- New Equipment Review

- Lifting Machines and Tackles

- Tank Storage Vessel Area

- Colour Coding for Pipelines

- Maintenance System

- Transportation of Hazard

AUDIT REPORT

The team will present the key audit results to the auditee and their site management in an audit closing meeting conducted at the end of the audit. The purpose of this meeting is to formally communicate the findings and the assessment of the acceptability of controls and to ensure clarity of understanding. Within two weeks, the audit team will prepare and report audit findings and issues to the project team for corrective action. A detailed recommendation or action plan is prepared based on the "audit findings." The action plan contains implementable schemes, best practices, technologies, and innovative solutions for improving electrical, fire, occupational, and health safety, emergency preparedness, and response. Plan measures to be followed by the industry as per the short term, medium term, and long term Period.