CNG / PNG Station Safety (HSE) Audit

CNG / PNG Station Safety (HSE) Audit

Arvika Risk Management supports global clients by completing hundreds of environment, health, and safety (EHS), sustainability, and facility optimization audits annually. Unlike our competitors, we don’t hire subs or contractors; we use our own resources with their local knowledge and access to our global network of expertise. All of our Arvika RM auditors are experienced in the local laws and intent of the regulations, know multiple languages, and are trained to a client’s unique expectations for the audit program. We support multi-task EHS audits, special interest audits (e.g., PHA -Audit, Safety Audit, energy, dangerous goods storage, waste management, Warehouse, CNG / PNG Safety Audit etc.), ISO certification preparation assessments, internal audit team augmentation, and/or supply chain audits. We understand each company has unique components to Environmental, Social, and Corporate Governance (ESG) and work with you to ensure this stays a priority. During our audits our consultants provide a value add to the site personnel in answering compliance questions, providing best practices from their extensive auditing experience, and assist in continuing to grow a client’s EHS and sustainability culture.

Hazards and risks associated with gas stations

- Because of the high volatility of substances in a petrol station, there is always a risk of a fire and/or explosion if there is a source of ignition nearby (e.g., a naked flame, an electrical spark, cigarettes, or something similar).

- Petroleum products, including benzene, are a major source of hazardous chemicals at gas stations. Those who are working in gasoline stations are at risk of exposure to benzene. Petrol overflow contributes to an increase in the level of exposure to these chemicals.

- Poor maintenance, carelessness, housekeeping, mechanical faults, and robbery were found to be the major causes of occurrences of unsafe acts and unsafe conditions at fuel stations. RAC are work system design methods that can be used to address associated risks in a project.

CNG filling station statutory requirements

- According to Gas Cylinder Rules (2004), the cylinder must undergo hydrostatic testing every three years.

- A certificate of CNG kit, fitness, and hydro test results must be possessed by the driver at all times.

- Maintain the cylinder in good condition.

- Do not install LPG, propane, or any other cylinder in place of a CNG cylinder. It is unsafe and unlawful.

- It is advisable to have insurance coverage for the CNG kit along with the vehicle and accessories.

- The cylinder and valves will not be repaired. For the cylinder, no oil, grease, or lubricant should be used.

- Don’t change the colour of the cylinder.

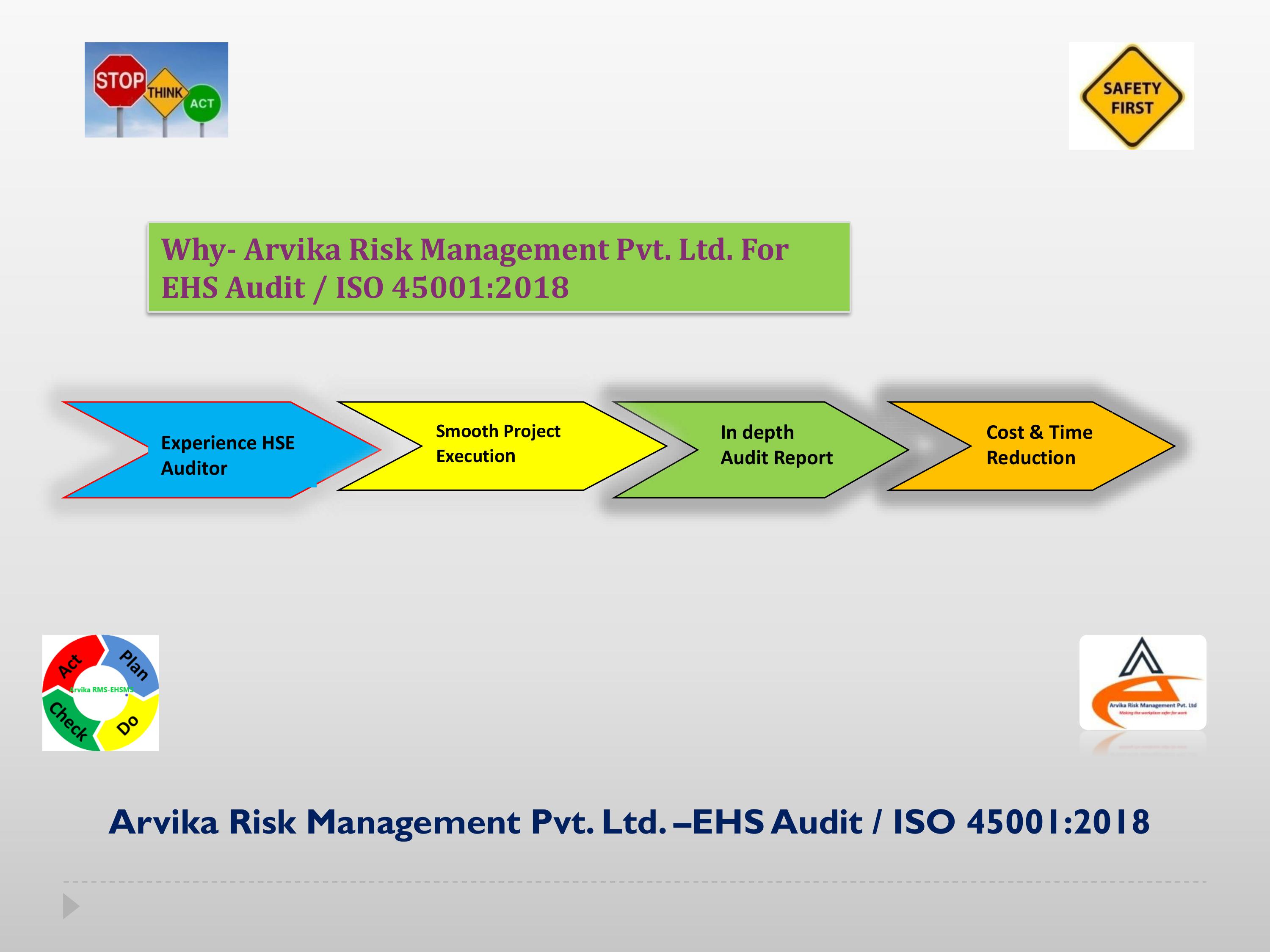

Why Arvika Risk Management Pvt. Ltd.

Important of HSE Audit

- Identifying gaps and conducting health and safety audits are important for challenging the benchmarks you’ve set out in your safety management system.

- They’re really helpful for coming up with actionable steps you can take to improve your business’ safety and can be used to:

- Document that your safety management system complies with legislation.

- Test to see if your safety management system is achieving its objectives.

- See if your safety management system is maintaining the performance criteria and if the auditing system is effective.

- Assess whether your organisation has completed any previous modification compliance audits, when necessary.

- Constantly improve your organization.

Key Results

- Consistent audit approach to reduce EHS compliance risks

- Assurance HSE Plan and its improvement

- Continual HSE Development assurance Plan