HAZOP Training

Hazard and Operability Study

HAZOP, or a Hazard and Operability Study, is a systematic way to identify possible hazards in a work process. In this approach, the process is broken down into steps, and every variation in work parameters is considered for each step, to see what could go wrong.

HAZOP history

The basis for HAZOP was laid by ICI in 1963 and was based on so-called "critical examination" techniques.

First guide: "A Guide to Hazard and Operability Studies," ICI and Chemical Industries Associations Ltd., 1977

HAZOP Study Process

A-Build a HAZOP Team

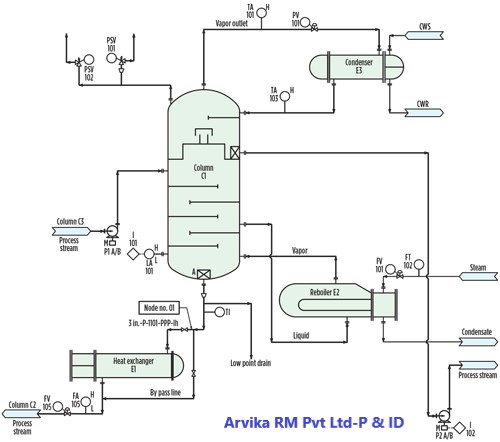

B-Identify processes, P & ID, and HAZOP nodes

C- Define the parameters, determine deviations, and select guide words.

D-Identify controls and establish safety monitoring

E-Communicate HAZOP results and improve processes

Types of HAZOP

Process HAZOP

The HAZOP technique was originally developed to assess plants and process systems

Human HAZOP

A "family" of specialized HAZOPs. More focused on human errors than technical failures

Procedure HAZOP

Review of procedures or operational sequences sometimes denoted SAFOP – SaFe Operation Study

Software HAZOP

Identification of possible errors in the development of software

HAZOP Steps

Success factors

Key Benefits of the Course